Fob price $ 11,840.00

The RO industrial water purifier will removed all contaminants, like solids, bacteria, algae, viruses, fungi, minerals such as iron, manganese and sulphur, and man-made chemical pollutants including fertilisers.

The reverse osmosis industrial water purifier can treatment different raw water like: city water, borehole water, underground water, river water and salt water as source water.

5000L RO industrial water purifier cost 6700liter resource water per hour and produce 5000 liter purified water for use. It mean also produced 1700 liter wastewater per hour. It is fit for nep-4000bph water bottling plant and nep-6000bph water bottling plant. It also can fit nep-200 5 gallon bottle water production line.

parameters of 5 ton industrial water purifier machine

| Capacity purified water | 5000 Liter per hour |

| Cost raw water | 6700 Liter per hour |

| RO membrane | 5 psc 8040 or DOW BW30-400 |

| Quartz sand filter | Flow: 8 m3 ton per hour Media: 800 kg carbon |

| Active carbon filter | Flow : 8 m3 per hour Media: 300 kg of quartz sand |

| Precision filter | 8 set PP filter 5u 1000 Flow 8M3 |

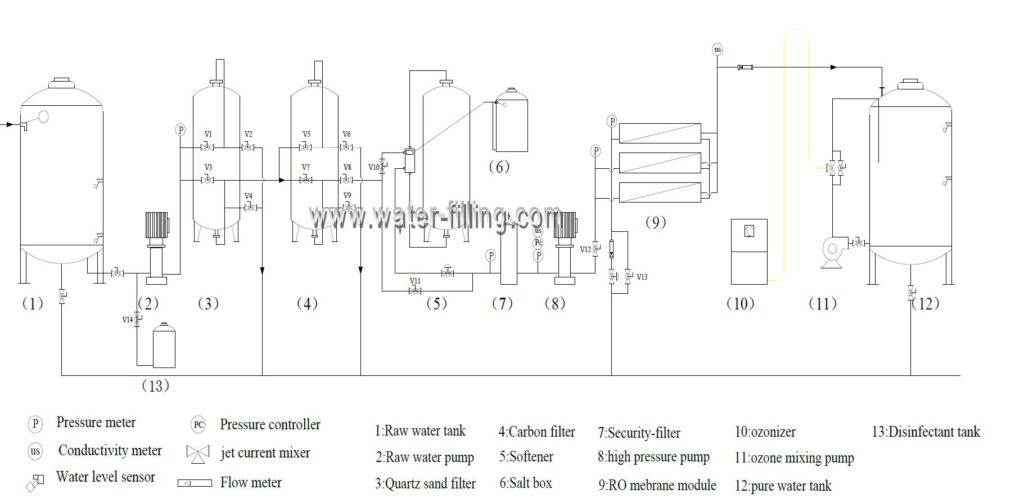

5000L/H RO Industrial water purifier technical process

The water is first being removed the suspended matter, micelle and other impurity by the quartz sand filter. Then it is being got rid of the organic substance, chlorine, chroma, odor and etc by the active carbon filter. The above two steps compose the consummate pretreatment system. The water which is being pretreated reaches the requirement of the RO system. So as to make the RO equipment run stably during a long period.

The abio-salt, organic substance, bacteria, heat source and other impurity in the water have been removed after the water was being treated through one grade RO system. The ratio of salt-doffed is in the range of 97%-99%. The water quality is accord with requirement of Hygienic standard of bottled purified water for drinking GB 17324—2008.

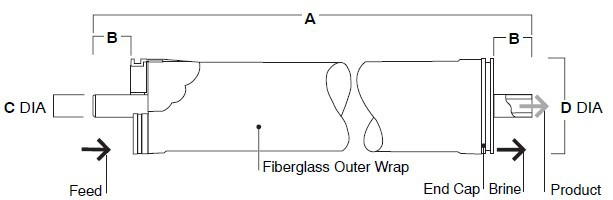

RO Device

The RO device removes the hydronium, organic substance, colloid, bacteria and other impurity by the method of membrane. And the water can be desalted and purified. The theory is as follows. The treated water and the untreated water are separated by the membrane; the treated water osmoses to the untreated water. There is osmotic pressure between the two. If the pressure is added to the untreated water and the pressure of the untreated water is bigger than the osmotic pressure, the water of the untreated water osmoses to the opposite position of the water. This applies the reverse osmosis to the desalted water. That is to say the untreated water is purified into the pure water through the RO membrane under adequate pressure. The left water which can not osmosis through the membrane contains a lot of solute and suspended substance, and it will be drained out as waste water.

The water must be pretreated before entering into the RO system, or it will bring damage to the RO membrane.

The RO system not only can be used for desalination, but also for filtering the organic substance and bacteria.

The production of water is monitored by the liquid crystal display conductivity meter.

The RO system needs be cleaned timely, including the stainless steel pump, filter, disinfectant tank, valve and other components.

Commonly, the RO system should work once every day. If it does not work in one week, it must be protected by some measures, or the service life of the membrane will be serious affected.

RO device employs low pressure large flux membrane made by American Dow Company. The type is American Dow BW30-400 Ro Memebrane, and it has nine of them. The membranes can serve for years in good maintenance. This instruction explains the details of operation and maintenance methods. The RO device removes the hydronium, organic substance, colloid, bacteria and other impurity by the method of membrane. And the water can be desalted and purified. The theory is as follows. The water and the solution are separated by the membrane; the water osmoses to the solution. There is osmotic pressure between the two. If the pressure is added to the solution and the pressure of it is bigger than the osmotic pressure, the water of the solution osmoses to the opposite position of the water. This applies the reverse osmosis to the desalted water. That is to say the raw water is purified into the pure water through the RO membrane under adequate pressure. The left water which can not osmosis through the membrane contains a lot of solute and suspended substance, and it will be drained out as waste water.

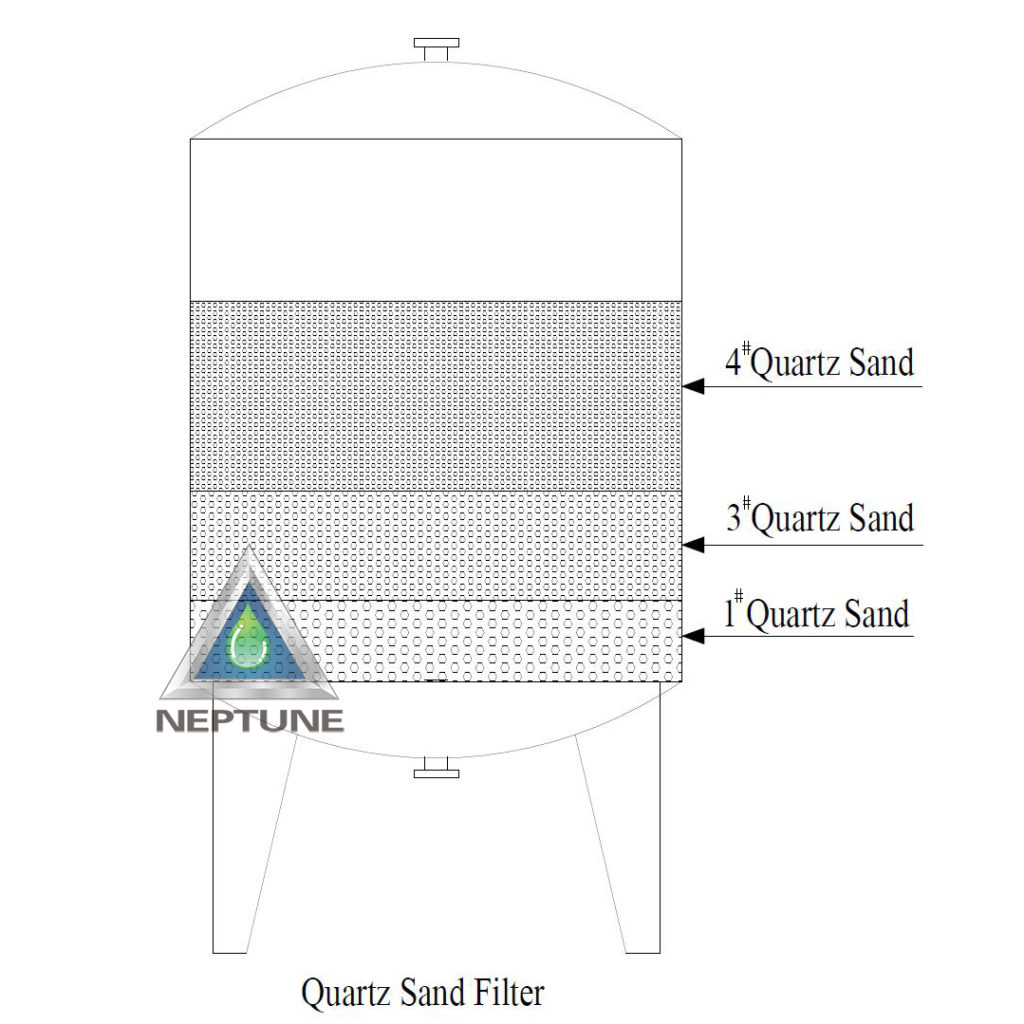

Quartz sand filter, prepare Filter for RO Device

The RO membrane is expensive and the most important fiter of one RO water purification machine. In order to longer the RO membrane life so that fit the quartz sand filter and active carbon filter

Quartz sand filter (Optional manganese sand)Removed big suspendid of raw water.Remove different types of particles, such as suspended solids (turbidity), colloidal compounds and

The design of single pressure filter is adopted in this system. In order to protect the back-end filters, we adopt one pressure filter. After a period of time, the filter will be saturated. In order to restore its function, the filter needs backwashes. In order to achieve its best results, the efficient backwash needs taking 20-30min. This filter is fitted with two diffusers, a manhole for discharge media.

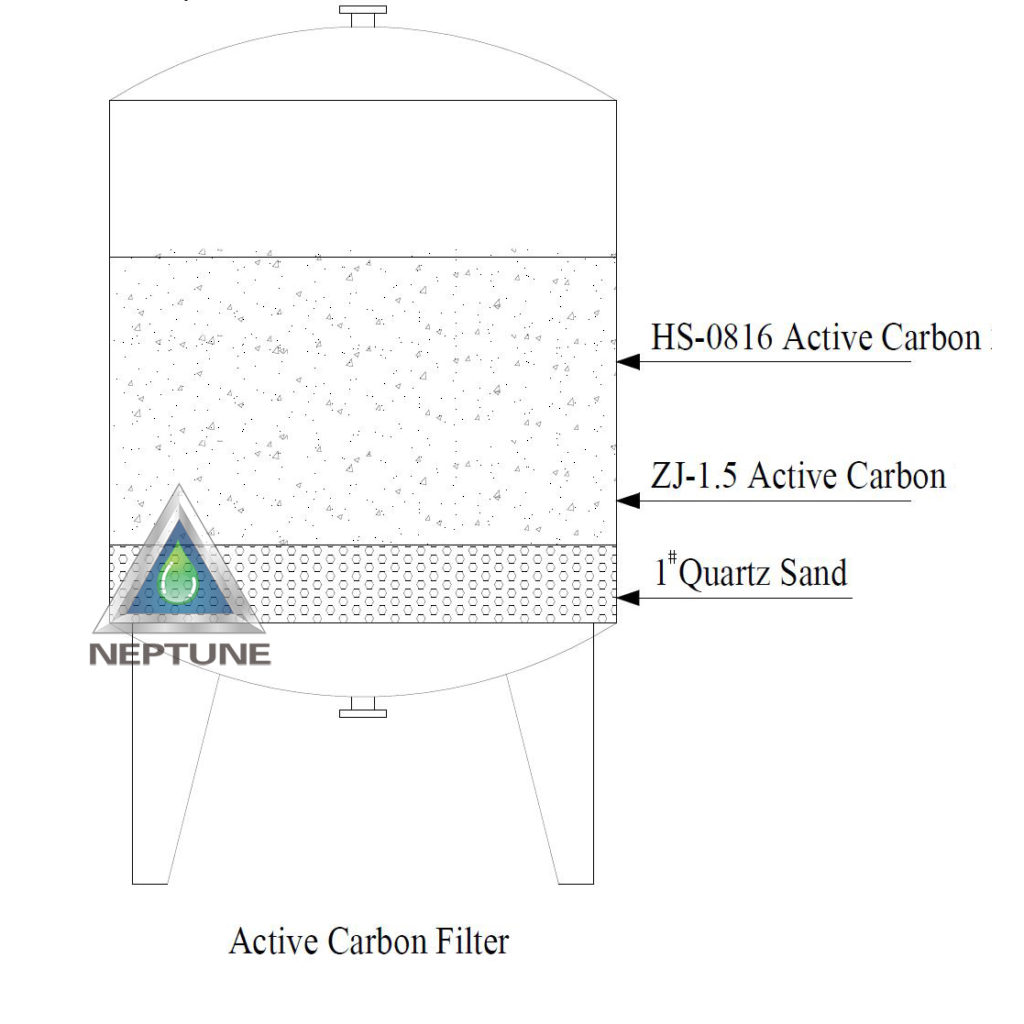

Activated carbon filter, prepare Filter for RO Device

Active carbon filter remove of organic substance and heavy metal element, suspended solids and etc. It can effectively reduce the level of COD and improve the taste of water.

With a valve operating system, pipeline system, containing the manhole, hand hole, the upper and lower water distribution devices, media, pressure.

The designed flow the 8m3/h. After a period of time, the media will be saturated and it needs backwashes. In order to achieve its best results, the efficient backwash needs taking 20-30min. This filter is fitted with two diffusers, a manhole for load media..

Precision filters, prepare Filter for RO Device

Prevent the particles entering the membrane, scratched the surface of the membrane. In the normal operating condition, the filter can maintained for 3 mouth. The filter structure for fast replace. Manufacture of high quality PVC material. Filter holder containing a fixed The 5μm PP filter is most commonly used for dealing the pure water. It is generally believed that the harmful particles and bacteria are larger than 0.22μm.

In order to prolong the life of RO system, the whole system adopts one set of stainless pp filter. The polypropylene microporous filter cartridges with the length of 40 inch in 5μm filters respectively. The 5μm filter acts as the protector of the RO system, filtering the vast majority of particles in the water, which eases the load of RO system and prolong its life. The filter cartridges are for one-time use, as the particles retained in the gap of microporous filtering film is hardly removed by rinsing with acid-base.

After a period of time, the filter cartridge needs to be replaced. The structure of them makes replacement of cartridge convenient. This apparatus contain filtration cartridges and stainless support layers. The support layer is made of stainless steel 304, with the advantages of compact structure, beautiful shape, high flux, good filtration accuracy and etc.