fob Price $ 14,300.00

It is an highly automated bottled water PVC sleeve shrink labeling machine. It contains two parts. First, auto sleeve label on every pass bottled water on the conveyor belt. Then the bottled water with label conveyor pass the hot-gas thrink tunnel.

Sleeve shrink labeling machine can sleeve different kind of bottle types. for example: round bottles, square bottles, flat bottles, curved bottles and cup-shaped bottles, etc.

It made use of PVC label physical properties which will naturally shrink by hot temperature.

| Capacity of production | 6000 bottles per hour |

| Materials | PVC label |

| Applicable Product | Bottled Water, Bottled Juice, Bottled Coke |

| Bottle Volume | 200ml-3000ml |

| Sleever Power | 3KW |

| Shrinking Power | 15kw |

| Voltage | Setting according customer inquiry |

| Main machine dimension | 2200L×1100Wx2000H |

| Applicable diameter of bottle body: | 28mm~125mm |

| Applicable thickness of label | 0.03mm~0.13mm |

Why Choice Neptune Sleeve Shrink Labeling Machine ?

- The label rack can easy adjust which fit an lot label.

- The sleeve labeling machine install is simple. Easy for both square and round bottle.

- It is use automatic controlling feeding system. It can level-off the sleeve label film materials and adjust strain simultaneity.

- It is use unique design knife plate. Do not need change knife and base if the label small different size. Also it is easy to change knife and base if need.

- It is use label location system which can promote and demote in-phase adjust location according to specific bottle type requirement.

- It is use high-sensitivity photoelectric which can make sure cutting label high precision.

- It is use advanced man-computer Interface auto controlling technology.

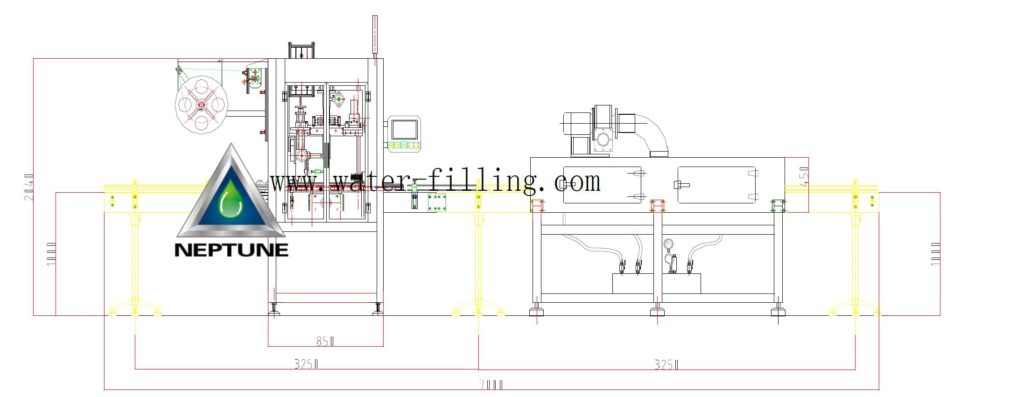

Layout Of The Sleeve Shrink Labeling Machine

The conveyor belt from beging to end total long 7meter. It run through the sleever machine and shrink tunnel. The conveyor belt is drive by the motor.

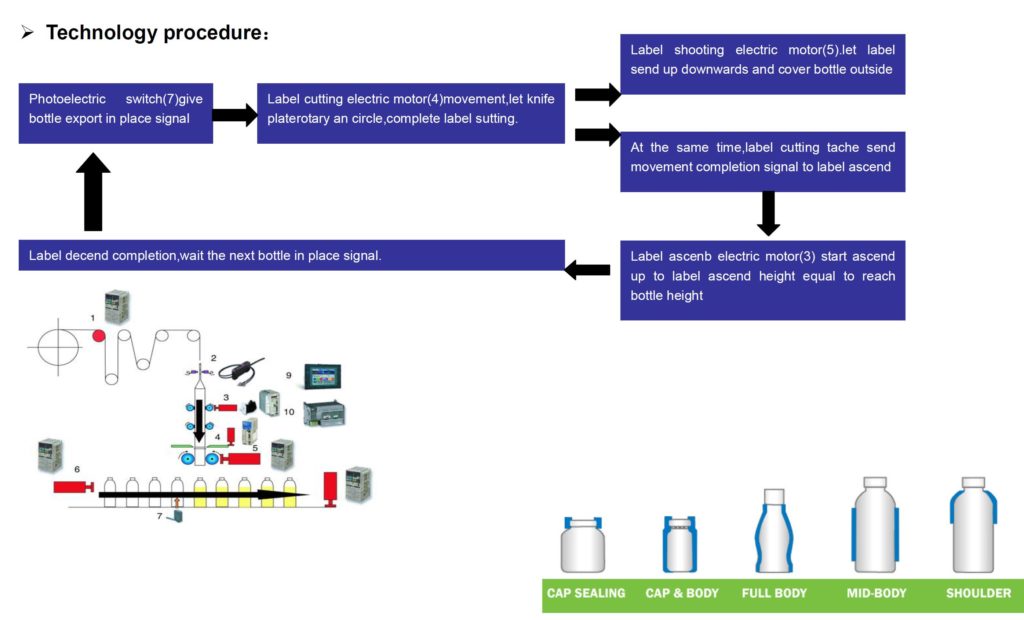

How Does Bottle Sleeve Labeling Machine Work?

All bottled water is conveyor by the belt. Knife plate will automatic cut an label and sheet it sleeve on the bottle while high sensitivity photoelectric read the bottle passing.

So every bottle passing with an sleeve label, but it do not tight on bottle. Then bottle with PVC label go through the shrink tunnel which have high tempature steam. The steam will heating the PVC label and made it shrinking. Then the label will got tight on the bottle.

The Secret Why Most New Bottle Water Brand Use Shrink Labeling.

Most old brand is use sticker labeling way. It is popular in past 20years. But more and more new bottled water company choice sleeve labeling way. Let’s compare the raw materials cost of the two labeling way.

Customer profit is our biggest happiness. A lot old bottle water company consultation us about shrink labeling machine and shrink label. And made order new sleeve labeling machine and sleeve shrink label to instead their old sticker labeling machine and sticker label.

Sleeve labeling materials cost just 20% of the sticker label. And it also beauty and never fall down. Every customer also like shrink labeling which do not have any sticker. It is the most new bottle water company’s choice.

Why they are a lot company still use sticker label,first they are old famous company which customer custom it. Second sticker label can do some special design which some special beauty bottle water company like it. They do not care about too much raw materials cost, and their bottle water average cost high.

1psc 500ml Label Will Save 0.02-0.004=0.016 Dollar

Compare PVC Label With Sticker Label

10million label*0.016dollar=160000dollar

An nep-2000bph water filling line plant 1years can produce 10million bottled water

PVC Shrink Label

500ml PVC shrink label usually cost USD 0.004. Its mainly cost at printing. The plastic film cost less

Sticker Label

500ml Sticker label cost USD 0.02 . Its over 5times cost than PVC shrink label.