fob Price $ 7300

What this price included:

- 2Cavity Blowing Bottle Machine

- Heating Oven equipment

- High pressure air compressor(0.75M3/30KG);

- Air Dryer with 2psc Air filter

- Two cavities blow mold (200-2000ml)

- Spare part & High pressure Pipe

- Mold cooling air chiller

The cost of a blow molding machine can vary greatly depending on a number of factors, such as the size and type of the machine, the materials it is designed to work with, and the complexity of its features.

It is also important to consider the cost of any additional equipment or tools that may be required to operate the blow molding machine, as well as the cost of the raw materials and other consumables that the machine will use.

Semi-automatic water bottle making machine is a type of machinery that is used to produce plastic water bottles. It typically consist of a series of different components, including a heating unit for melting the plastic, a mold for shaping the melted plastic into the desired bottle shape, a blowing unit for holding the mold and blowing plastic bottle, and a cooling unit for solidifying the plastic.

This pet water bottle making machine once can produce two piece plastic bottle. A lot bottled water company first start making plastic bottle with this bottle blowing and making machine. It is the smallest and cheapest bottle blowing machine in the world.

It is widely used to produce 100-2000ml carbonated bottle, mineral water, pesticide bottle oil bottle cosmetics, wide-mouth bottle etc.

Technique Parameter of 2cavity water bottling making machine

| Product material | PET |

| Volume | 100ml to 2000ml |

| Theoretical output | 800 Bottles/h |

| Preform length | 15mm-350mm |

| Preform inner diameter | φ5mm-38mm |

| Max.mould plate Dimension(L x W) | 350x380mm |

| Max.mould thickness | 180mm |

| Clamping force | 45KN |

| Mould opening stroke | 160mm |

| Main blowing machine (L x W x H) | 160x60x161cm |

| Main blowing machine weight | 500Kg |

| Heater oven (L x W x H) | 187x63x145cm |

| Heater oven weight | 250Kg |

| Power inquiry total | 17.5kw |

Video Of The Water Bottle Making Machine

It need worker manul insert pet-preform on oven and carry the heating well preform to the blowing unit.

And then need worker press the button to start blowing plastic pet bottle

Adopting double crank to adjust mould ,heavy locking mould, stable and fast ,Adopt infrared oven to heat the perform ,the perform rotated and heated equally.

The air system has been divided into two parts: pneumatic action part and bottle blow part to meet the different requirements for the action and blow .It can provide sufficient and steady high pressure for blowing large irregular shaped bottles.

Advantage

The machine is also equipped with muffler and oiling system to lubricate the mechanical part of the machine.

The machine can be operated in the step-by-step mode and the semi-auto mode.

The machine is small with low investment, easy and safe to operate.

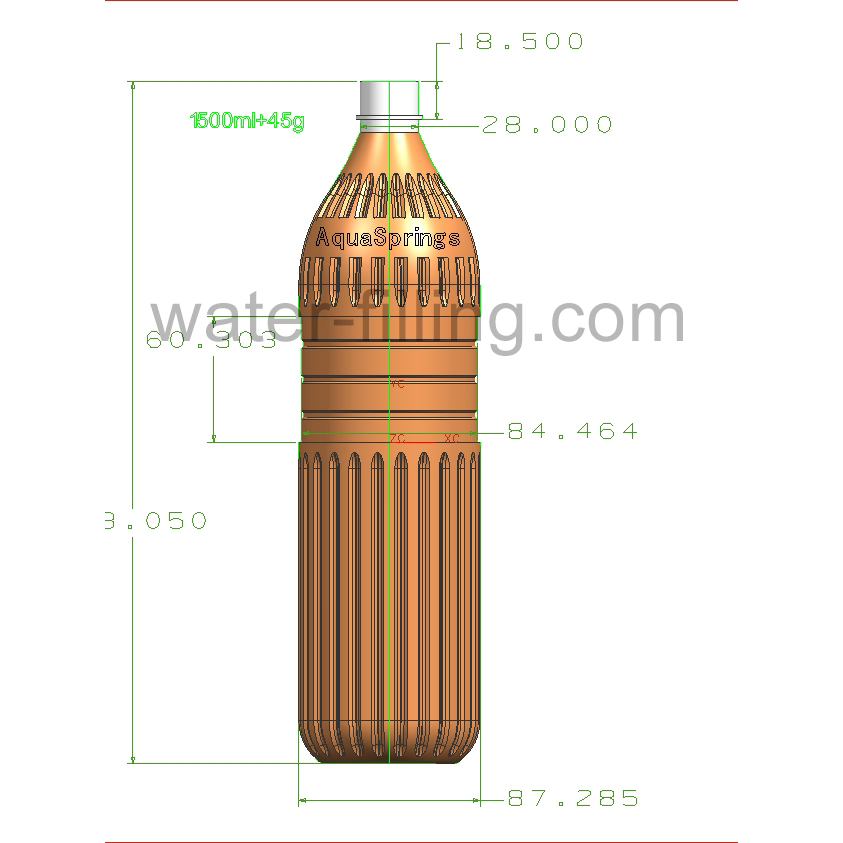

Got An Beauty Bottle Design

NEPTUNE machinery have expert engineer drawing and design the plastic pet bottle. They are professional and experienced.

Every plastic bottle design mark and line must 100% clean when it prodution into an really pet plastic bottle.

The bottle design structure must good. So that will not easy fall down on conveyor belt of water production plant. Can not easy fall down shop freezer.

Got An Art Plastic Bottle

An beauty plastic bottle will attract consumer. When it show on Shelves of supermarket. People will been attract by it. And want touch it and have an detail look.Then maybe more purchasing. Anyway, an bottled water is not expensive. A little attract will let consumer buy it.

Equipment list of an complete Water bottle making machine

Easy and safe use. It is the blowing plastic pet bottle part unit.

It is the heating oven which used to heating the pet preform.

The high pressure air compressor supply air for blowing the bottle.

Air dryer with 2psc filter which use to clean and purified the air from the air compressor.

It is used to cooling the blow mold. Make sure the bottle making process continued. It is optional equipment.

Through change blow bottle mold and can produce different shape and volume bottle.