Water PET bottle Blowing machine 6000 Bottles Per Hour

Fob price $ 67,000.00

What This Price Included?

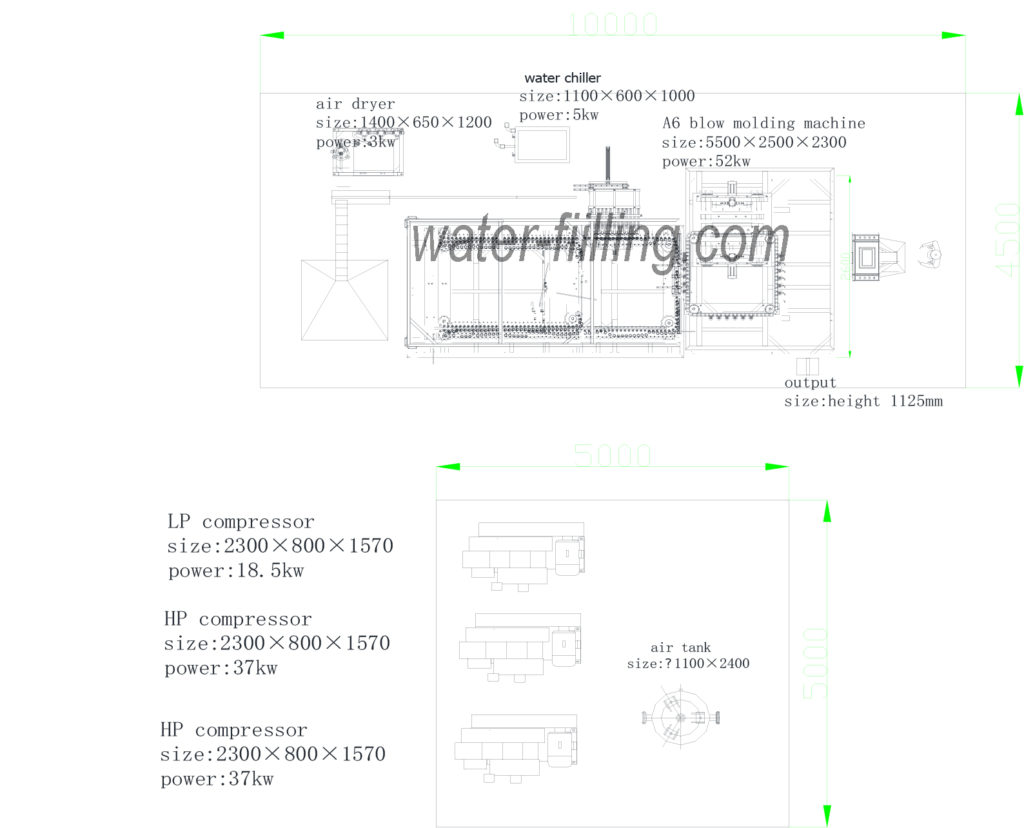

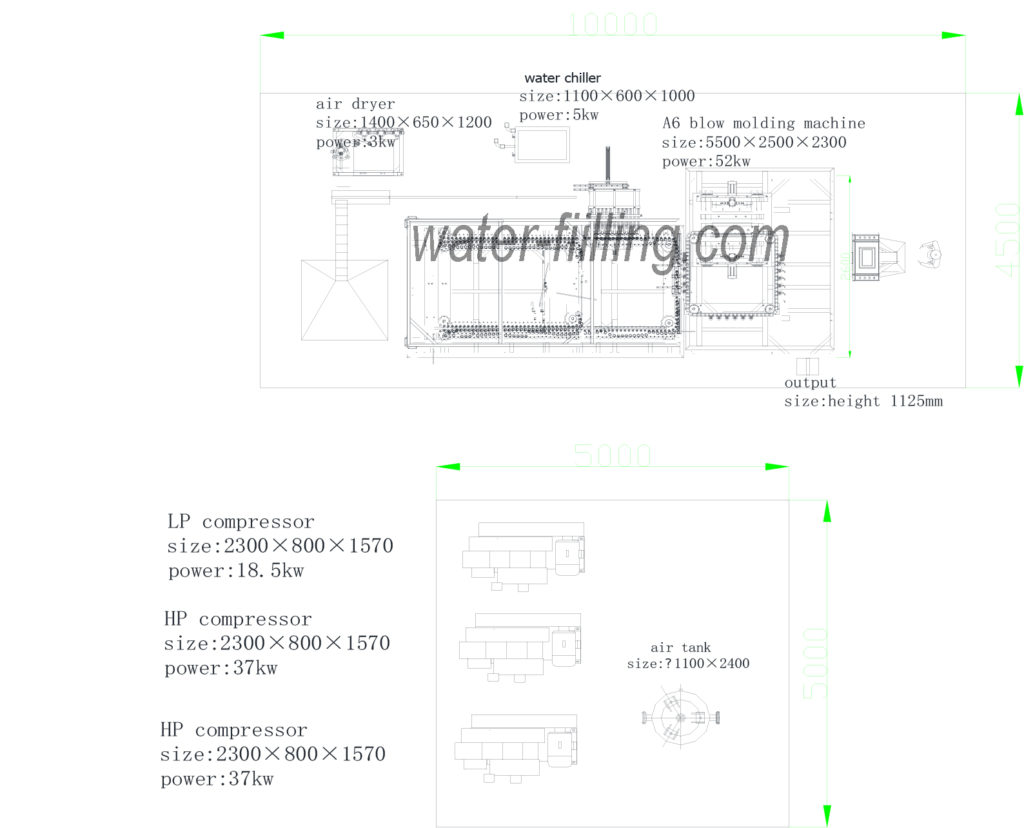

| Automatic Blow Molding Machine | BM-A6 |

| Auto Preform Loader | BM-A6 |

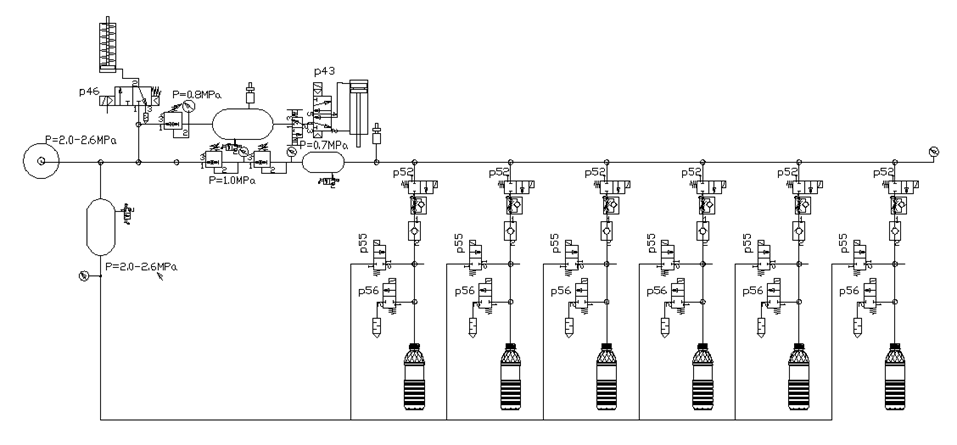

| High Pressure Air Compressor Unit | 3.2m3/min; 30Kg |

| Low Pressure Air Compressor | 1.6m3/min; 10Kg |

| HP Air Dryer | 6.0m3/min 30Kg |

| HP Air filter | 6.0m3/min 30kg |

| HP Air Tank | 1.0 m3/min 30Kg |

| Mould Chiller | 5HP |

| LP air filter | 2.0m3/min; 10Kg |

| Spare parts | / |

| Air tube | / |

| Blow Mold | Six cavity |

PET Plastic Bottle blow molding machine 6000 bottles per hour 200ml to 2000ml pet plastic bottle which widely used to conntainer water, beverage and oil.

Main Technical Parameters And Dimensions

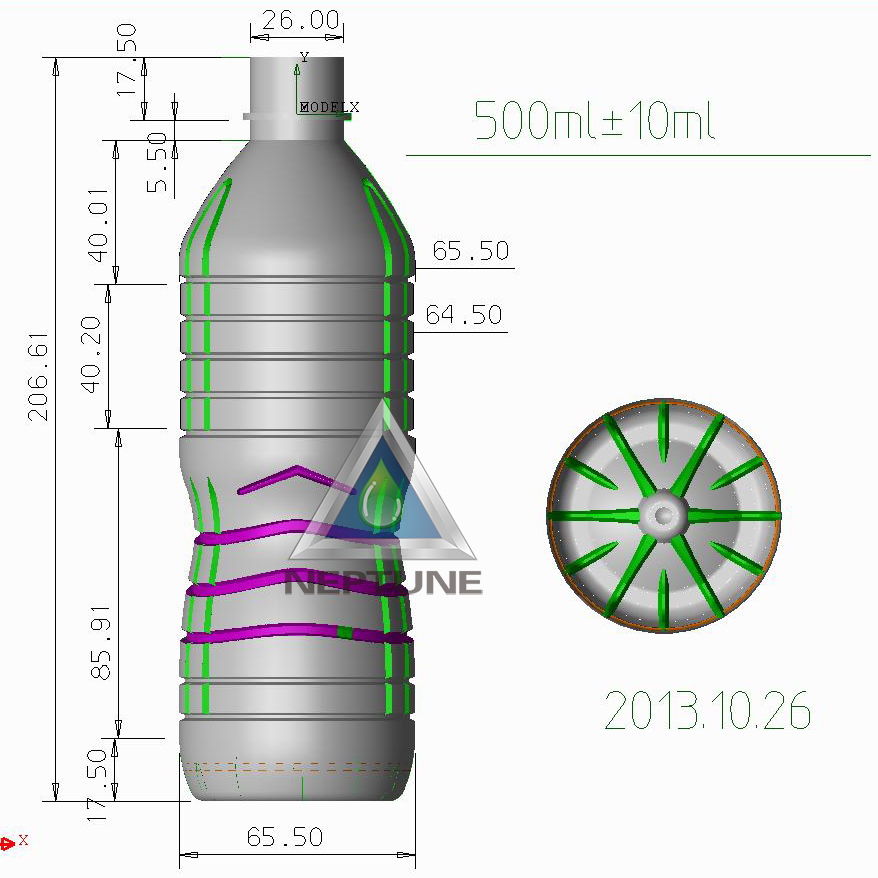

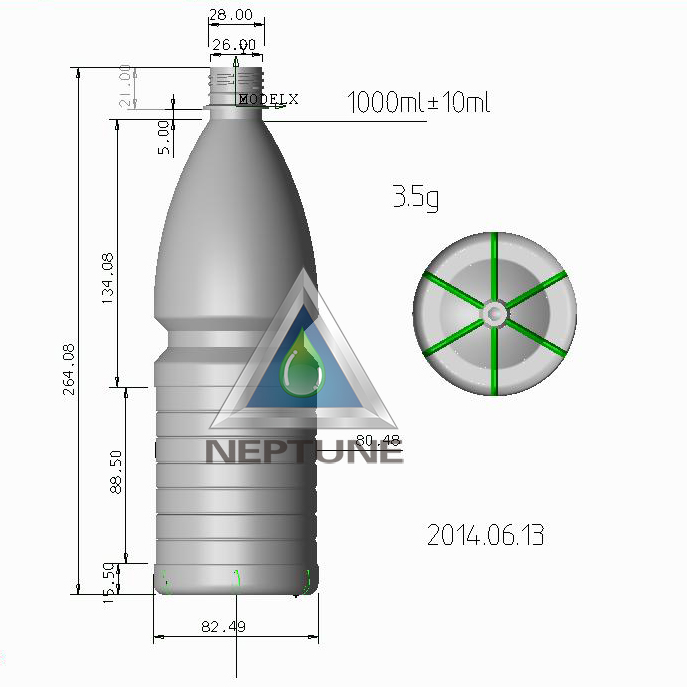

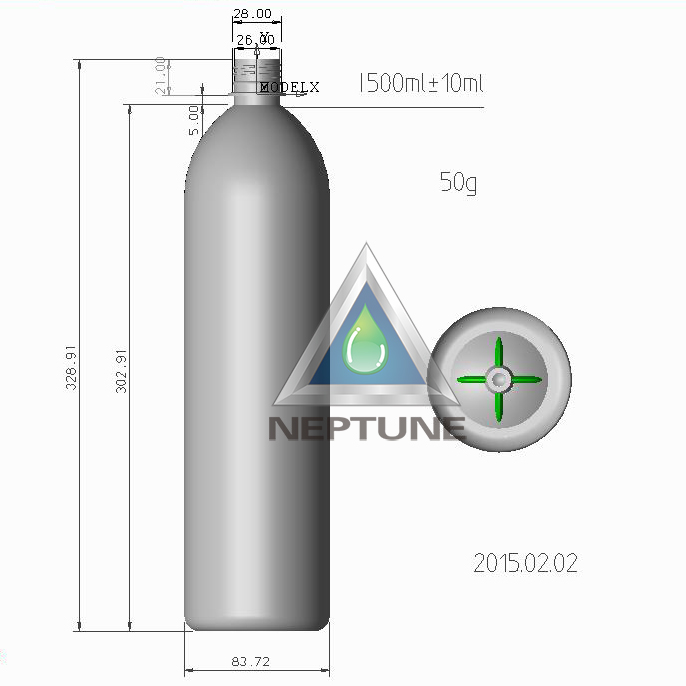

| Capacity of production | 6000 bottles per hour depend on 500ml bottle 5000 bottles per hour depend on 1000ml bottle 4000 bottles per hour depend on 1500ml bottle |

| Bottle height | 50mm-320mm |

| Biggest bottle diameter | 200mm |

| Power Inquiry | 120kw |

| Really use power | 40kw |

| Voltage | Default 380v/3phase/50hz. Can be order other voltage |

| Working pressure | 0.8mpa |

| Blowing gas pressure | 1.6-2.5mpa |

| Dimensions | 7088mm long, 2060mm width, 2000mm high |

What is Water PET bottle Blowing machine ?

It is suitable for producing PET plastic containers and bottles in all shapes. It is widely used to produce the carbonated bottle, mineral water, pesticide bottle oil bottle cosmetics, and hot fill bottle etc.

Water PET bottle Blowing machine 6000 Bottles Per Hour stable performance with advanced PLC. Strong penetrability and good and swift distribution of the heat by letting the bottles ratate by itself and revolute in the rails simultaneously in the infrared preheater.

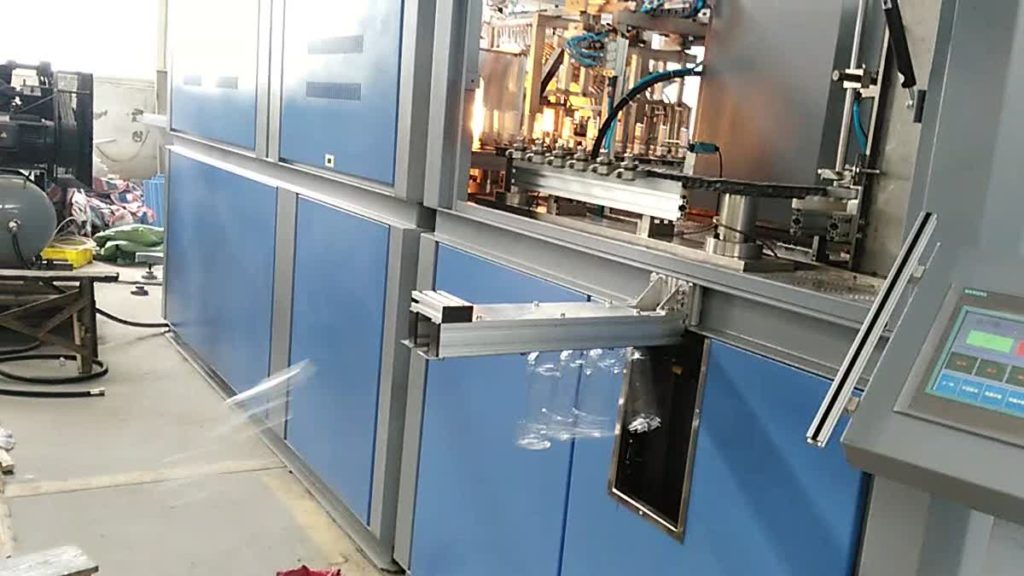

The 6 cavity blow molding machine for Water bottle

automatic Preform loader

Blowing plastic bottle

Air conveyor outlet bottle

Struture And Principle

6000bph PET Plastic Bottle blow molding machine is equipped with automatic feeding, automatic preform loading, infra-red heating, blowing mechanism, stretching mechanism, mold clamping machine and automatic bottle blowing. Nine institutions.

1.Automatic Feeding Device

Automatic feeding device consists of two parts of the silo conveyor belt: 1. silo slope design with three sides to prevent the preform to stay. 2. special conveyor belt allows a smooth and sufficient amount of preform blank into the device. The preform delivery can be based on the actual situation, adjust the speed of the delivery motor to be achieved.

2.Automatic Blank Device

Automatic blank device from the oblique bucket, roller billet and other parts of the composition. The preform provided by the loading device is directly slid into the oblique bucket, and the upward rotation of the preform is carried out through the drum. The preform is arranged in the guide track which has been adjusted the distance between the two rollers, and is not arranged in the slide The preform is returned from the blank to the oblique drum, and the above operation is repeated. The preformed preform is placed at the manipulator through the intermediate runner so that the preform can be loaded.

3.Preform Automatically Enter:

Stay in the middle of the preform slide, through the action of the robot to load preform loading device into the main loop.

4. preform loading device

Preform loading device from the bottle care, the board consists of two parts:

1, the bottle care: the ball spring reasonable assembly in the care of the body, through the ball spring bottle preform thread and keep the ring with the ingenious, to achieve loading and unloading, the purpose of carrying preforms.

2, the board: According to the model, the bottle asked to install the board in the joint board, the board will be carrying a bottle in the main circulation for the closed cycle.

The preform is heated and blown by the circular motion of the bottle holder.

5.infrared heating device

The heater use infrared glass lamp, gold-plated single-sided technology to deal with, to improve the heater heat utilization.

Heater by the computer and microcontroller (PIC) control of its high stability, accurate and rGRid adjustment.

Depending on the preform, heater parameters through the operation of man-machine interface to change the heating distance can be adjusted.

2. Oven: Using the latest design to achieve a good preform heating environment, the oven

The hot air evacuation device makes the heating effect of the preform particularly good.

3. Cooling: To prevent the surrounding parts of the oven temperature, and cooling the bottle, the cooling of the bottle will directly affect the quality of the finished product. GR series models using cooling water circulation design, cooling effect is particularly good, the bottle will not be hot deformation, which is superior to other models of the latest design.

6.blowing mechanism

The product blows the gradual way product to form evenly, this kind of blowing way is far superior to the ordinary model.

Gas installation, the use of special design, activities, sealing the gas source. GR series of aircraft will be fixed installation, original design, much better than the traditional activities of the installation design, high and low pressure mixed gas, the choice of one-way isolation, safe and reliable.

stretching institutions:

GR series of machines using single-cylinder double-stretching device, this device will be conducive to two-stretch synchronization, tensile shock buffer selection.

7. Stretching institutions:

GR series of machines using single-cylinder double-stretching device, this device will be conducive to two-stretch synchronization, tensile shock buffer selection.

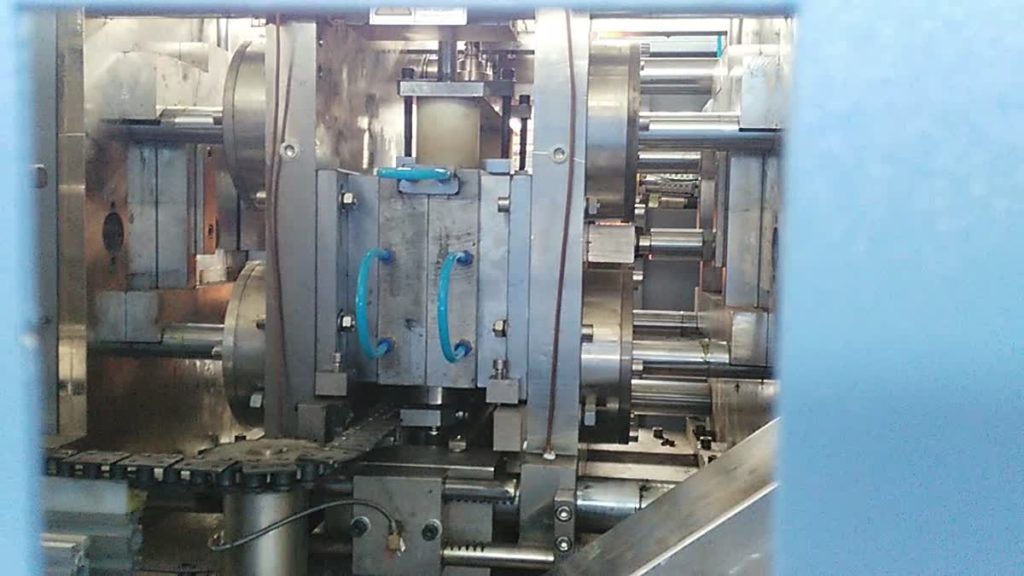

8.mold clamping machine

The clamping machine adopts three-plate linkage structure, the movement is steady and fast, the mold clamping has air lock, and the gas mechanical compound lock, the clamping performance is good.

9.Automatic bottle device

From the bottle-out cylinder and mandrel, so that the bottle from the bottle care into the bottle out of the conveyor belt, the conveyor belt and then neat conveyor out of the machine.

layout of 6000BPH auto bottle blowing Machine

Bottle design of blow mold