fob price $ 9,800.00

What this price included:

1. Automatic Bottle Wrapper

2. Automatic Shrink Tunnel

Water bottle shrink wrapper auto wrapping 6/12/24 psc bottles with film. Then automatic moving the it to shrink tunnel blowing hot air to make it tighten.

The automatic bottle shrink wrapper is widely used in bottle beverage, bottle medical-chemical and bottled water package. It can make package perfect whatever it is without pallet, catoon, rectangle, round or flat shape. It has the advantage of less cost and better appearance.

- It applies PLC automatic controller, man-machine interface, ensure that no fallen bottle, no bottle shortage.

- It adjusts flexible, safe and beautiful.

- The adjustable hot wind recycle structure make machine suits for all kinds of thermal films(including color printing).

- Replace film conveniently. It has failure alarm, lock device, reliable runnig.

parameter of the water bottle Auto Shrink Wrapper

| Capacity of production | 8000 bottles per hour depend on 500ml bottle |

| Volume of bottle | 200ml to 5liter |

| Power | 23kw |

| Weight | 950kg |

1. Automatic Bottle Wrapper

The bottle clamp will arrange 3 or 4 line bottled water enter. Then the setting well clampboard and buffle will decide how many bottled water one package.

The wrap film unit will wrap and cutting film well. And let the package bottled water enter the next shrinking tunnel

| Power | 3kw |

| Packing speed | 0~13pcs/min |

| Conveyer loading | 20kg |

| Weight of film roller | ≤15kg/roller |

| Max. packing size | 500(L)×300(W)×400(H)mm |

| Min. packing size | 250(L)×50(W)×100(H)mm |

| Machine size | 1060(L)×1600(W)×1930(H)mm |

| Weight of machine | 350kg |

2. Automatic Shrink Tunnel

The package bottled water will film go through this tunnel by conveyor belt. And the film will auto shrinking when it face hot temperature. So that it will got tight the bottled water.

| Power | 20KW |

| Conveyor speed | 0-10m/min |

| Conveyor load | 50kg |

| External size of the machine | 2500*820*1680mm |

| Packing size | 500*400mm |

| Thick of film | 0.03-0.25mm |

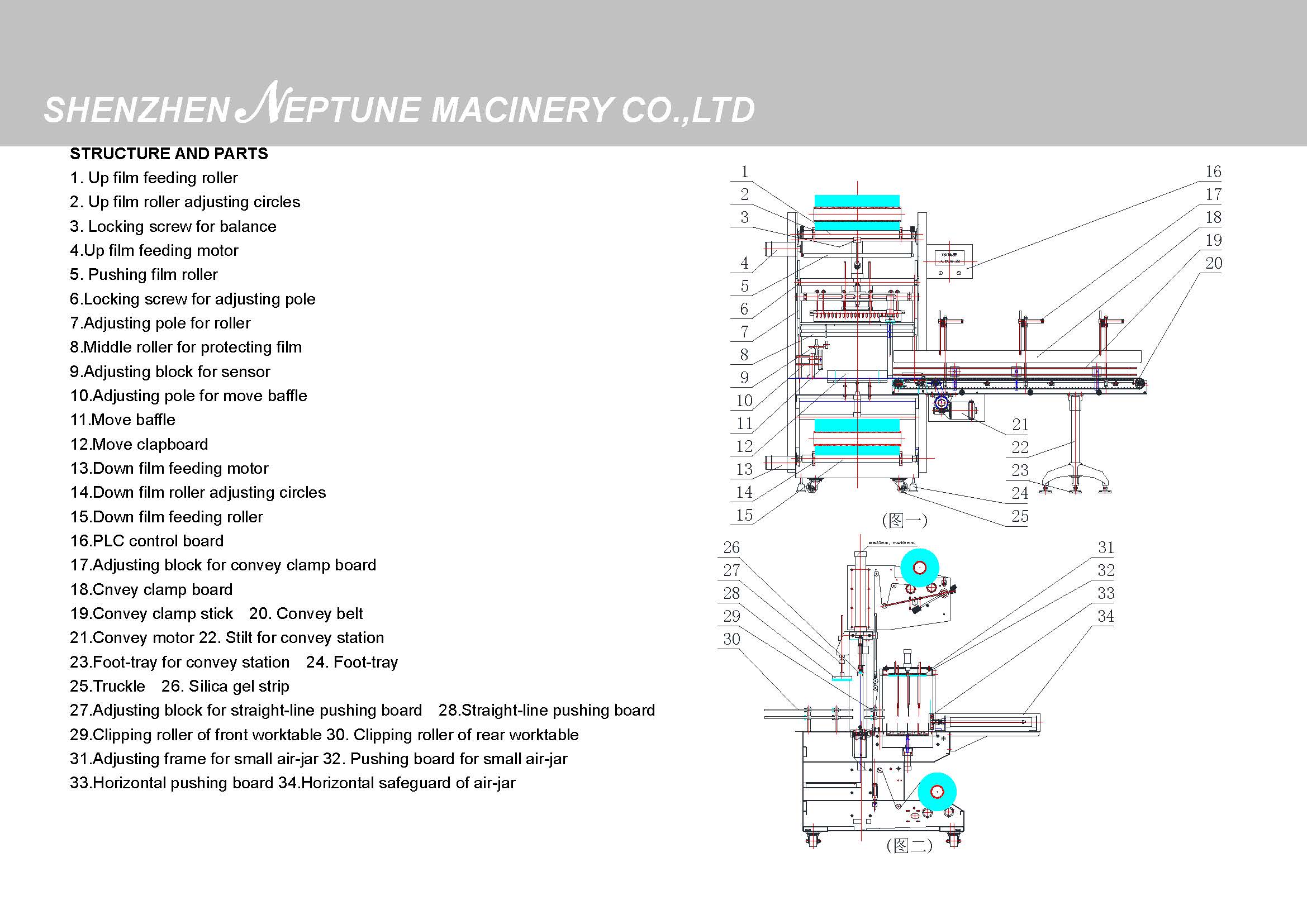

Structure And Parts Of Automatic Bottle Shrink Wrap Machine

Equipment consisits of following parts:

Bottle conveyor device: transfer goods which need package.

Block bottle, dispart bottle device: transfer packages in separateway and control strock of package.

Block bottle position inspecting device: separate bottles to package and consequent bottles.

Pushing bottle, guild bottle device: Pushing bottles to sealing and cutting.

Film fix length conveyordevice: transfer package film.

Sealing&cutting device: seal and cut package film.

Hot wind recycle device: To fulfill thermal shrinkage function.

Heat resistant conveyor device: Transfer finished products under high temperature, and fulfill thermal shrinkage function.

Finished product storage device: storage products temporally.

Colling device: Cool product so that convenient transfer products to required position.

PLC control system: Automatic control to an unknown typesetter.

wrapping film, anti-dirty

The automatic bottled water wrap film and shrinking package machine only cost less than 10k dollar when an automatic bottled water carton package machine will cost about 30k dollar.

And the wrapping film package is anti-rain and anti-ditry. No easy been dirty or wet by rain or water.

A lot supermarket and shop like carton case because they can sell the case. And bottled water consumer just got 1psc or 2psc bottled water from the shelf. Most consumer can not saw the package.

Wrap Film, save materials cost

Wrap film 1kg cost USD 2.5 depend on oil price change. 1kg can package 22psc package. Per piece bottle water wrap film cost USD 0.005

1psc Carton case will cost USD0.45 just can package 24piece 500ml bottle water. Per piece bottle water carbon case cost USD 0.0189

So that, an 500ml bottle water cost wrap film and carton case different at USD 0.0139

If an bottle water factory production 3Million bottle water per year. Use two kind of package way materials cost different at USD 41818

video of Advanced Water Bottle Shrink Wrapper

The bottle and box which need to be packed is transferred to block bottle plate along dispart bottle device.

The bottle conveyor will stop when photoelectrical inspector on the top send out a signal, while block bottle plate stand back to release pressed force of bottle.

The separate plate up rises to separate packing bottle and bottles to be packed. Push bottle device pushes packing bottle and film along with guils bottle device to sealing&cutting position, meanwhile pushes the last package onto conveyor of thermal shrinkage equipment, meanwhile film feeding device is working.

Then the thermal sealing&cutting move downward, to sealing and cutting. The package which been pushed onto thermal conveyor is go ahead and finish thernal shrinking function, finally it goes to strong device after colled by cold wind.

The above processing fulfills automatic packing.

The above movements are all done by air cylinder under PLC control, except conveyor system.