Factory Directly Selling 5 Gallon Water filling Machine

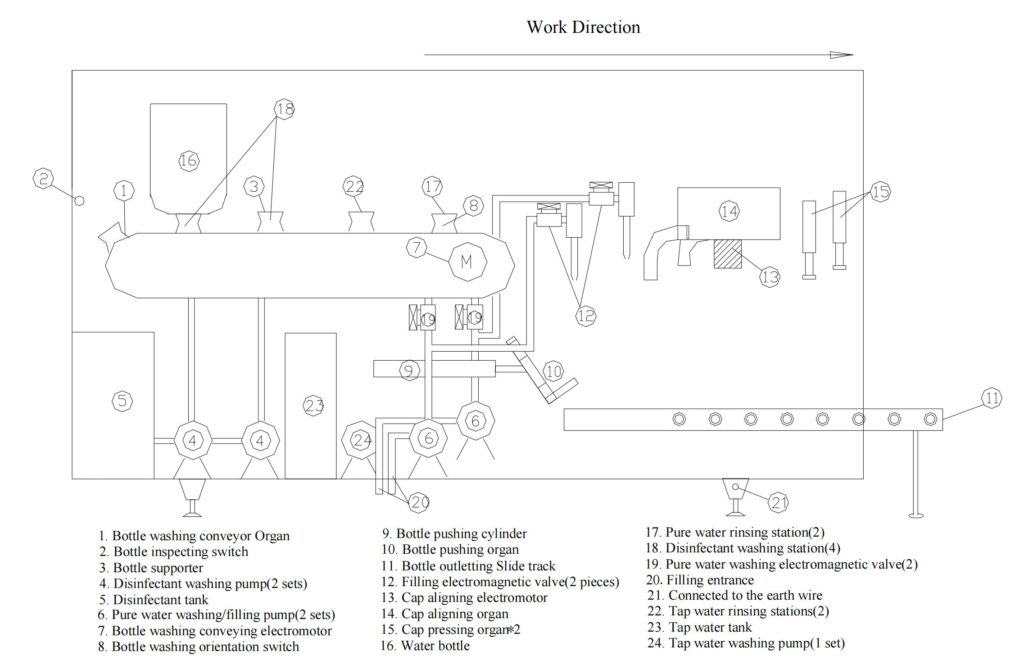

The 5 gallon water bottling machine collect bottle washing, filling and capping together. It can used to filler and bottling 3 Gallon to 6 Gallon bottled water.

5 Gallon filling machine is not only the mainly bottling machine of 5 gallon mineral water plant , but also can lonely as an 5 galllon water refill station.

Parameter of the 20 ltr water jar filling machine

1. Volume of bottle: 3 Gallon, 18.9 Liter , 19 Ltr , 20 Ltr, 5 Gallon, 6Gallon

2. Drink Kind: Mineral Water, Pure Water, Spring Water.

- High automatization

- Easy operation

- Reliable performance

- Small size, small weight

- Anti-corrodibility

It reach the standard of America Drinking Water Industry Association.

Key components of electrical appliances and metal materials manufactured by famous brand.

5 Gallon Water Filliing Machine Price list

60 Bottles/H

$2500PLC, Motor, 2M conveyor

| Total power | 1.5KW |

| Net weight | 200kg |

| Outer size | 2330×680×1550(mm) |

| Requirement of water supply | 1400Liter Per Hour |

100 Bottles/H

$2900PLC, Motor, 2M conveyor

| Total power | 2.0KW |

| Net weight | 260kg |

| Outer size | 2960×670×1550(mm) |

| Requirement of water supply | 2500Liter Per Hour |

200 Bottles/H

$3170PLC, Motor, 2M conveyor

| Total power | 2.8KW |

| Net weight | 380kg |

| Outer size | 3220×980×1600(mm) |

| Requirement of water supply | 5000Liter Per Hour |

300 Bottles/H

$4380PLC, Motor, 2M conveyor

| Total power | 7.3KW |

| Net weight | 430kg |

| Outer size | 3525×980×1600(mm) |

| Requirement of water supply | 7000Liter Per Hour |

450 Bottles/H

$7770PLC, Motor, 2M conveyor

| Total power | 8KW |

| Net weight | 480kg |

| Outer size | 3800×1250×1600(mm) |

| Requirement of water supply | 11000Liter Per Hour |

600 Bottles/H

$13200PLC, Motor, 2M conveyor

| Total power | 10.7KW |

| Net weight | 680kg |

| Outer size | 3800×1710×1830(mm) |

| Requirement of water supply | 13000Liter Per Hour |

Video of the 5 gallon water filling machine

Push Washing

The 5 Gallon Water Filling Machine mainly machine included 4 station push washing.( Optional add more washing station)

- Pure water push washing for prepare.

- NaOH food-grade medicine push washing

- City water push washing

- Purified water push washing

Worker just need turn over load empty 20ltr plastic bottle into machine.

It have 4 row washing station. 1th and 2th washing station are disinfection. You can setting it use food-grade NaOH washing in case the recycle jar inside have chemical. 3th washing station is city water push inside washing. 4th washing station is pure water washing.

Then the 20 ltr jar machine will flip the bottle 180 degrees and filler pure water into the bottle. The machine come with water pump and PLC. The filling time can be setting easy by button or by PLC so that can adjust filler water level.

Then filler well bottle water conveyor to pressure capper. The machine have an cap tank which can hold an box cap. The cap will automatic take turn to pressure on the bottle mouth.

Working Process Of The 5 Gallon Bottle Water Filling Machine

First, Plastic empty 5 gallon bottle enter and been push washing by pure water. Second washing by NaOH water, it can kill bacteria and neutralize other chemicals if have. Third washing by city normal water for pre-washing. Four final washing outside and inside by purified water.

After push washing, the bottle will been dropped down and bottle will been seated on the bottle pushing supporter. Then is the key filler pure water into the bottle water. It can be easy setting filling how many second to got enough level of the 5 gallon bottled water.

Good quality

The complete 5 gallon water bottling machine is manufactured by high-strength stainless steel materials with precise argon arc, little distortion and fair welding veins.

The conveying component structures made of stainless steel to assure good running under various conditions. Nonmetallic components are manufactured elaborately by wearable materials, such as nontoxic PP plastic, etc.

In order to make sure the machine running more stable. The conveyor motor and pressure is use the NO.1 brand of China. All electrical components manufactured elaborately by famous internation brand.

Filler and capper

The bottled water will been pushed to the right position to pressure capping and then the filled well bottle water will be conveyor outlet.

All bottling process is controlled by PLC. Its have function of high automaticlly and precise orientation.

advanced 5 Gallon water Bottling Machine

Factory directly selling. Transparent price.

The big bottle washing filling capping machine is strictly according to the China drinking water industry Association standards.

Most electrical components produced by China famous brand and key materials produced by international famous company.

Its is high automation, convenient operation and reliable performance.

Its size is small, whole machine weight is light and it has a beauty appearance. Its corrosion resistance is strong, its disinfection function is very good, it’s can effectively prevent air pollution to ensure the products have a high quality and so on.

The bottle filling machine entire process control by the PLC, precise positioning automatically, using less power, low labor intensity.

It made of high strength stainless steel, precision arc welding, variant small, beautiful welding lines; transmission parts for the stainless steel structure to ensure that the institutions in the normal operation of a variety of environments; non-metallic parts are made of PP plastic and other non-toxic high Wear-resistant materials carefully processed.The drive motor and the booster pump mostly use the domestic export-oriented series stainless steel products.Series of electrical components used imported or domestic famous series of hardcover which is more stable and reliable.