Make it easy to start bottled water business

Why Our Filling Machines Are So Affordable

As the source factory, we eliminate middlemen costs to offer you direct-from-manufacturer pricing. While our Model 883 filling machines are fully customizable, we achieve significant cost savings by producing them in batches of 50 units per order. This bulk production approach reduces per-unit expenses in:

Raw material procurement (volume discounts)

Labor efficiency (streamlined assembly lines)

Quality control (standardized testing processes)

Unlike competitors who produce small quantities or outsource, our integrated production facility ensures consistent quality while passing the savings to you. Our batch system allows flexible configurations without compromising economies of scale.

FOB Price $ 7,900.00

What this price included?

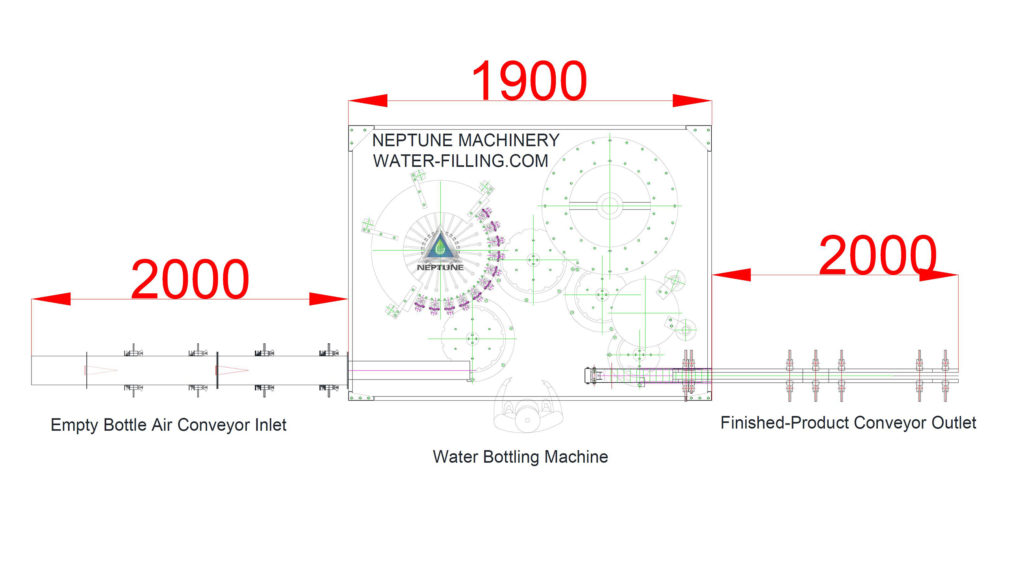

- 8-8-3 Water Bottling Machine 3-in-1 monoblock

- 2 meter empty-bottle air conveyor belt

- Air fan

- 2 meter product conveyor belt

- Electricity Motor

- Automatic water-cap loading and feeding machine

883 Water bottling machine is a revolutionary solution for small to medium-sized water bottling operations, offering efficient production at a cost-effective price.

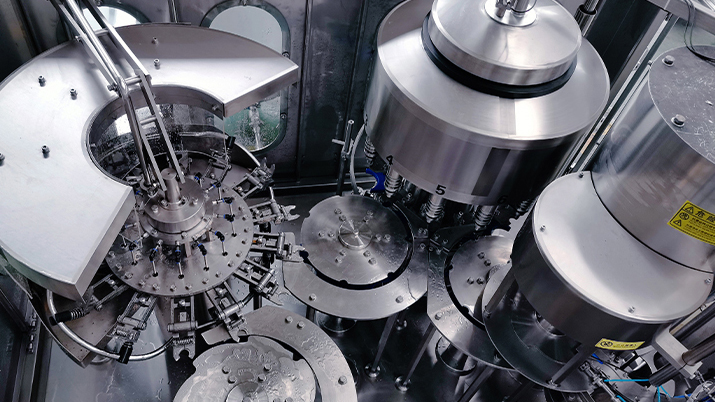

The world smallest monoblock rotary water bottling machine for 200ml to 2000ml bottle water. Collect 8psc rinser, 8psc filler and 1psc capper in one machine.

This bottling machine is a testament to innovation, providing an economical and practical solution for businesses entering the water bottling industry.

Optimized Capacity

Designed for a capacity of 2000 bottles per hour, it strikes a balance between efficiency and cost-effectiveness. Eight filling heads, eight washing heads, and three capping heads ensure smooth and consistent operation.

Compact Monoblock Design

The monoblock design collect the rinser, filler, and capper in one machine, saving space in your facility. Its compact footprint is ideal for businesses with limited space.

Synchronized Movement

The machine ensures synchronized movement of the rinser, filler, and capper with each bottle.This 360-degree movement allows for continuous and uninterrupted processing, optimizing efficiency.

Labor-Saving Automation

Fully automatic operation reduces the need for manual labor. PLC control system provides easy and precise control over the entire bottling process.

Cost-Effective Production:

The machine’s smaller capacity and efficient design lead to cost savings on materials and initial investment. Perfect for startups and businesses looking for a budget-friendly solution without compromising on quality.

User-Friendly Operation:

The water bottling machine is designed for ease of use, making it suitable for operators with varying levels of experience. PLC control simplifies setup and monitoring.

Continuous Operation

With no need for frequent stops, the 883 Bottled Water Filling Machine ensures continuous production, maximizing output.

Ideal for Startups:

Suited for first-time water bottling ventures, allowing them to enter the market with a reliable and cost-efficient solution.

What Is The Capacity Of 3-In-1 water Bottling Machine?

The production capacity of the 3-in-1 water bottle filling machine varies based on the size of the bottles being filled. Here are the details:

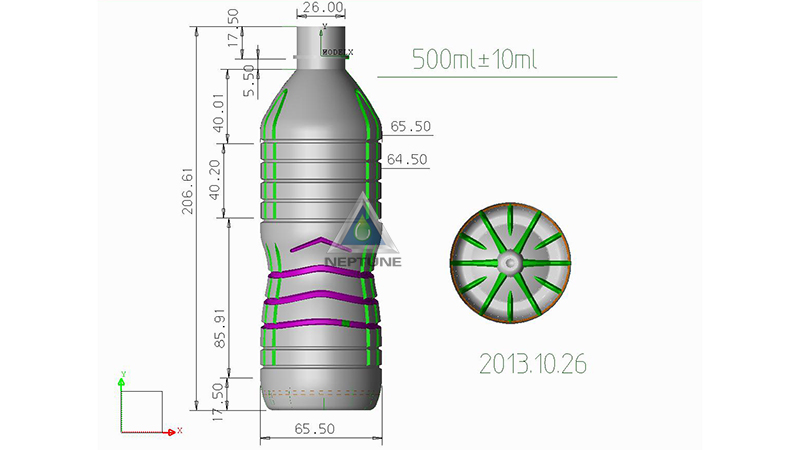

For 300ml to 600ml bottles: 2000 bottles per hour

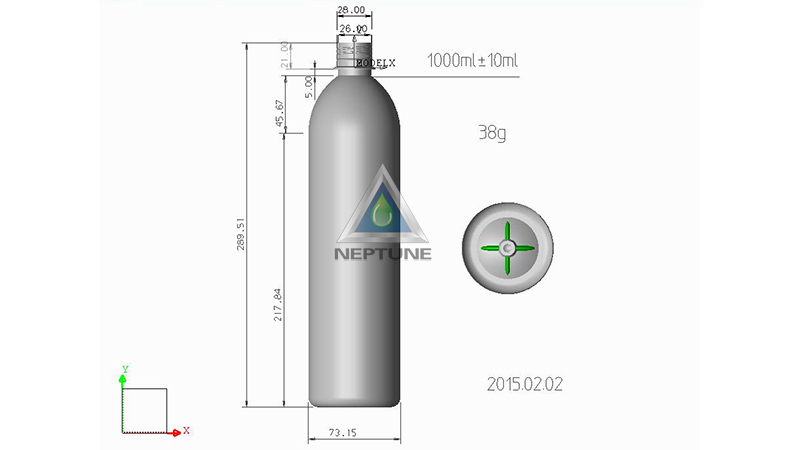

For 700ml to 1000ml bottles: 1500 bottles per hour

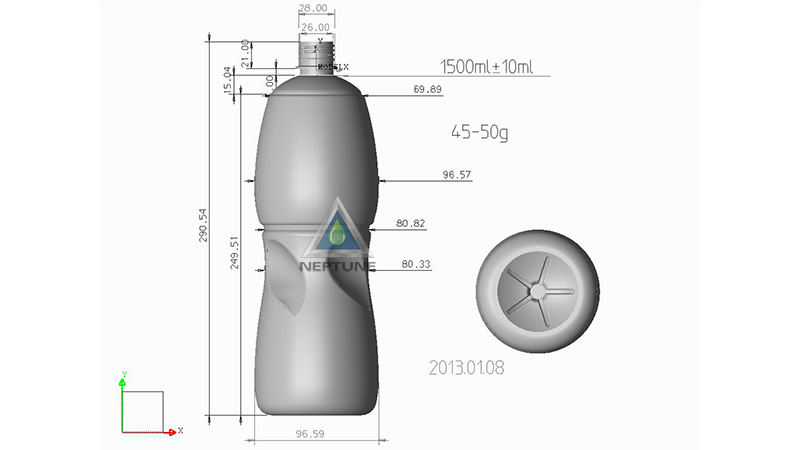

For 1500ml to 2000ml bottles: 1200 bottles per hour

The 3IN1 bottle water filling machine engineered to accommodate various bottle shapes, offering flexibility in adapting to different sizes and shapes for diverse packaging preferences. This adaptability empowers businesses to broaden their product range and meet varied market demands. Whether dealing with round or square bottles, irrespective of specific dimensions, the machine can be adjusted or customized to ensure efficient filling, capping, and labeling processes for a variety of bottle shapes within the water bottling industry.

Can The Machine Handle Different Bottle Sizes And Shapes?

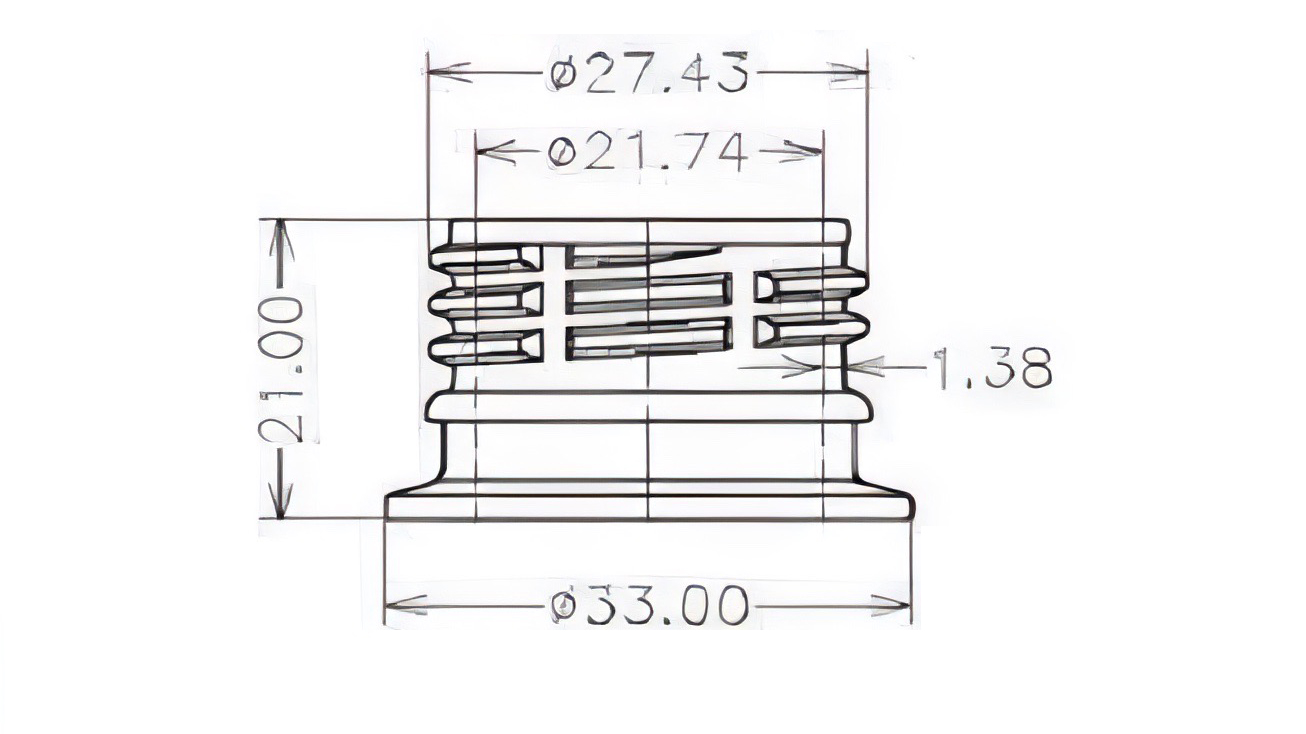

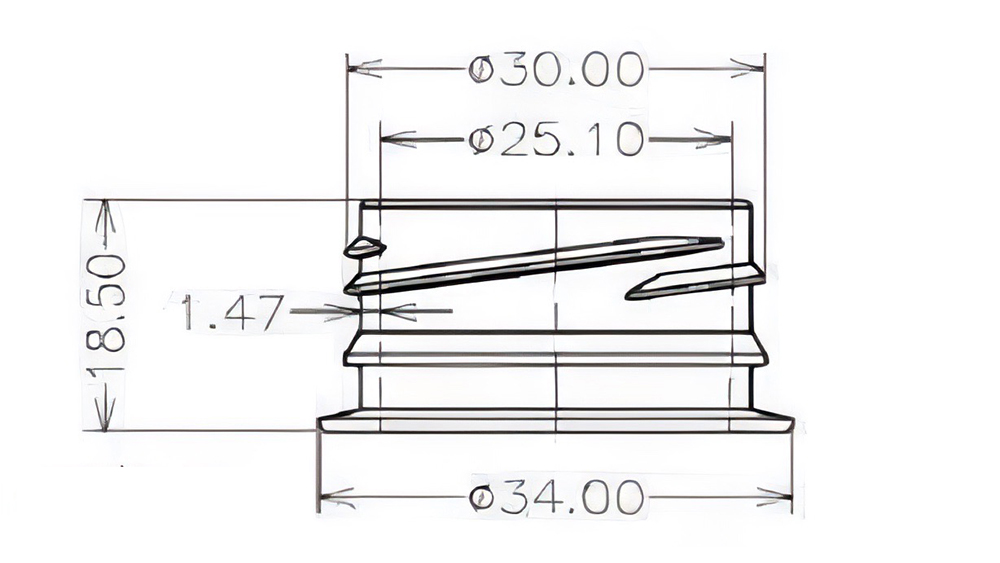

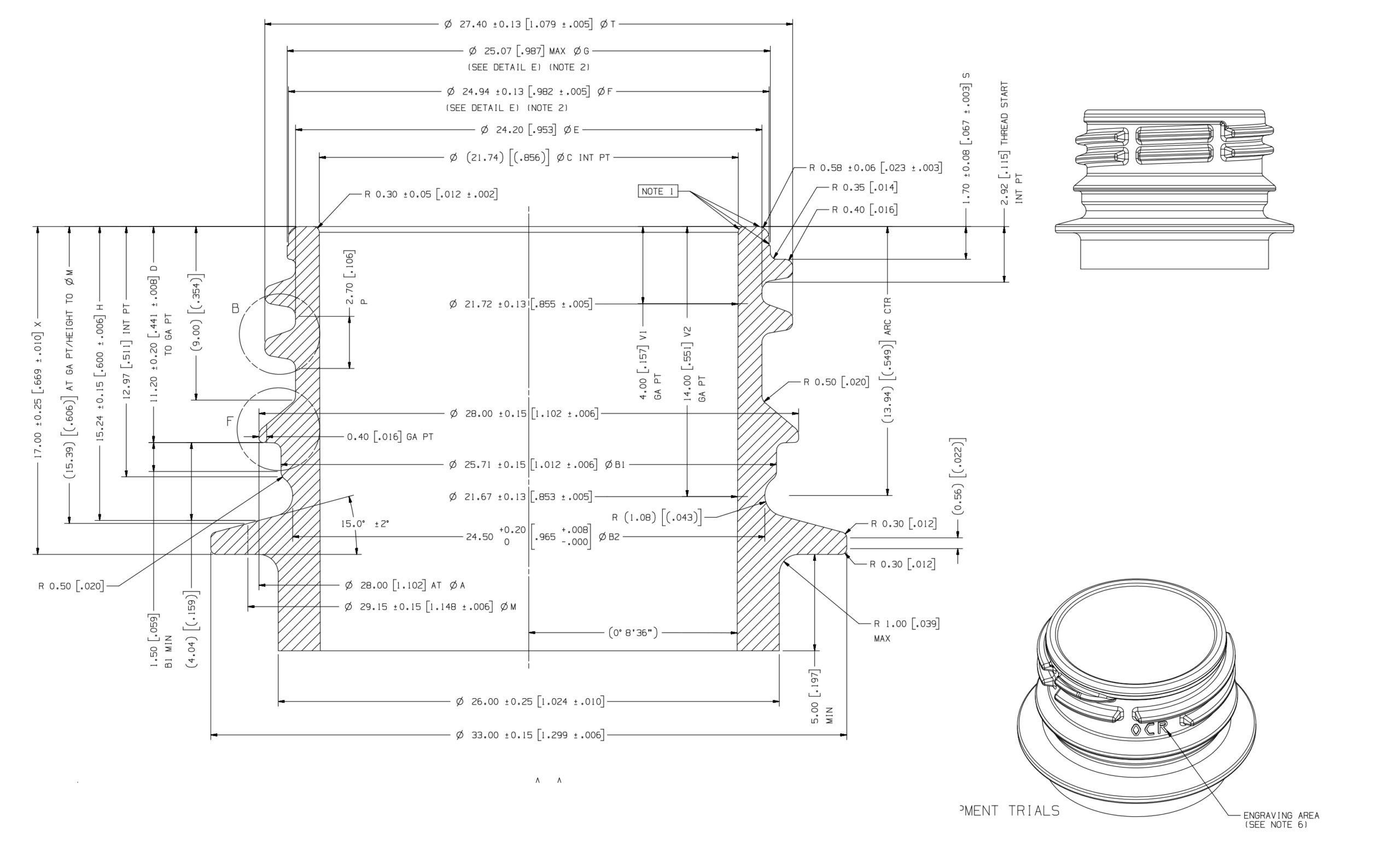

3-in-1 water bottling machine is crafted to manage a variety of bottle sizes and shapes. It is primarily crafted for screw-type bottles and caps, typically featuring a size of 28mm or 30mm. The machine is capable of handling bottle volumes ranging from 200ml to 2000ml.

In case of bottle and cap dimensions beyond the standard range, it is advisable to consult neptune machinery for custom settings. This adaptability ensures that the machine is well-suited for a diverse range of bottled water products.

All Inside materials use stainless steel 304

2000BPH water bottling machine 3in1 monoblock is a high-speed, stable, and user-friendly option for bottling water. This machine is capable of filling and packaging 2000 bottles of 500ml bottled water per hour, making it well-suited for medium to large-scale bottling operations.

The machine’s rotary rinser, filler, and capper allow for continuous bottling without any delays or pauses, making it an efficient and reliable choice for water bottling. Additionally, the machine is pre-configured and does not require any adjustments, making it easy to use for people with little experience in bottling operations.

The washing system is push washing outside and inside of the bottle to make sure it clean. The filling system is responsible for filling the bottles with water, and use gravity filling. The capping system seals the bottles with caps.

The production capacity of a 3in1 monoblock filling machine is typically measured in bottles per hour (BPH), and the speed of the machine can be adjusted to meet the needs of the bottling operation. These machines are commonly used in the food and beverage industry to produce bottled water for a variety of purposes, including drinking water, purified water, spring water, and mineral water.

Rotary Bottle Washing

Every rinser head is moving synchronously with bottle while washing the plastic bottle. It working around 360 degree disk. rotary plastic bottle washing machine works is by using a series of spray nozzles to rinse the inside and outside of the bottle

Overall, rotary bottle washing machines are a popular choice for bottling operations due to their high capping speed, flexibility, and reliability.

Rotary Bottle Filling

Rotary filling machines are called “rotary” filling machines because they use a rotating disc or turret to hold the bottles in place while they are filled. Every filler head is moving synchronously with bottle while filling water into the bottle. It working around 360 degree disk.

Another advantage of rotary filling machines is their flexibility. These machines can be easily configured to fill a wide range of bottle sizes and shapes, and can be easily adjusted to fill different volumes of liquid. This allows bottling operations to use the same filling machine for a variety of products and packaging sizes.

Rotary Bottle Screw Capping

Rotary screw capping machines use a rotating screw mechanism to apply caps or other closures to bottles or containers. Every capper head is moving synchronously with bottle while capping the bottle water. It working around 360 degree disk.

Rotary screw capping machines are also known for their reliability and durability. These machines are built to withstand the rigors of high-speed capping operations, and are designed to operate continuously for long periods of time without requiring frequent maintenance or repairs.

the production layout of the monoblock 883 water bottling machine

Automatic cap loading and feeding machine

Efficient 3-in-1 Water Bottling Machine Process

- Bottle Washing:

- Bottles are collected and placed on a rotary conveyor.

- The rotary rinser, equipped with washing heads, engages with each bottle. The bottle-clamp grips the bottle mouth and turns 180 degrees along a guide track.

- During this rotation, special nozzles eject a powerful stream of water, thoroughly cleaning the bottle’s interior.

- Bottle Filling :

- After washing, bottles move to the filling station.

- Neck-supporting carrier plates hold the bottles in place as they are raised to engage with filling valves.

- Valves open, and water, or the desired liquid, is precisely filled into the bottles. Once filled, the valves close, completing the filling process.

- Capping Procedure:

- Filled bottles are transferred to the capping station.

- Anti-rotation blades on capping heads seize the bottleneck to prevent rotation.

- The twist-on capping head completes the process with revolving and rotating movements, ensuring secure and sealed caps.

- Continuous Movement:

- Each washing, filling, and capping head moves with the bottle, making a 360-degree rotation.

- The synchronized movement allows for a continuous and uninterrupted bottling process without the need to stop or wait for other bottles.

- Output Conveyor:

- Completed bottles are then discharged onto an output conveyor belt.

- The conveyor transports the finished bottled water to the next stage in the production line or for packaging.

The seamless integration of washing, filling, and capping in a single machine streamlines the entire bottling process, ensuring efficiency and precision.

Parameter

| MODEL | NF 8-8-3 |

| Production Capacity | 2000-2500 bottles/h |

| Washing Head Quantity | 8 |

| Filling Valve Quantity | 8 |

| Capping Head Quantity | 3 |

| Filling Temperature | Normal temperature |

| Filling Type | Constant Pressure Filling |

| Main Motor Power | 3.42KW |

| Bottle diameter | 40-102mm |

| Bottle height | 130-30mm |

| Air resource pressure | 0.5Mpa |

| Filling Water | 1-1.5T/H |

| Consume Water | 0.8T/H |

| Control Type | PLC |

| Central Diameter of Filling Valve | 320mm |

| Central Diameter of Capping Machine | 120mm |

| Central Diameter of Washing Machine | 320mm |

| Dimension | 1850 X 1450X2000mm |

| Net Weight: | 1200kg |

Electrical Configuration

| NO | NAME | MODEL | UNIT | BRAND | NOTE |

| 1 | Main motor | Y90L-4 2.2KW | 1SET | China Suzhou | frame |

| 2 | Cover motor | YCJ90W-4 0.09kw | 1SET | China Taizhou | frame |

| 3 | Jet water pump | BJZ037S 0.376KW | 1SET | China Yuehua Pump | frame |

| 4 | Inlet pump | BJZ037S 0.376KW | 1SET | China Yuehua Pump | frame |

| 5 | Conveyor motor | UDL 0.37KW | 1SET | China Taizhou | frame |

| 6 | Air blower motor | Y802-2 0.75KW | 1SET | China Wuxi | frame |

| 9 | PLC | FX1S-20MR | 1SET | Mitsubishi | Electric control box |

| 10 | Inverter | FR-D740E-2.2K | 1SET | Mitsubishi | Electric control box |

| 11 | Breaker | DZ47-3P-D 20A | 1PSC | Schneider | Electric control box |

| 12 | Breaker | DZ47-1P –C6A | 1PSC | Schneider | Electric control box |

| 13 | AC contactor | CJX2-0910 | 6PSC | Schneider | Electric control box |

| Thermal relay | JRSD-25 | 6PSC | Schneider | Electric control box | |

| 15 | DC power supply | S-50-24V | 1PSC | China Taiwan | Electric control box |

| 16 | Terminal block | TD1545 | 1PSC | Tracy | Electric control box |

| 17 | Mushroom always stops | 01ZS | 1PSC | Schneider | electrical panel |

| 19 | Indicator light | AD16-22 | 1PSC | Schneider | electrical panel |

| 20 | Potentiometer | 1/2W 4.7K | 1PSC | China Shanghai | electrical panel |

| 21 | Touch screen | MT6070IQ | 1SET | China Taiwan Weilun | electrical panel |

| 22 | Proximity switch | PR18-5DN | 2PSC | AUTONICS | frame |

| 23 | Photoelectric switch | BR100-DDT | 3PSC | AUTONICS | frame |

| 24 | Cover feed motor | 0.37KW | 1PSC | China | cover delivery |

What is Monoblock & Rotary 8-8-3 water Bottling Machine

Batch production of 50 set 883 water filling machines at once, which significantly reduces costs.

What is rotary Water Bottling Machine?

Rotary water bottling machine is designed for optimal efficiency, with both valves and bottles moving seamlessly. Every step, from washing to filling and capping, features constant-speed rotation along the circumference. This high-speed, space-efficient system ensures top-tier automation and effectiveness, reflecting our expertise in bottling technology.

What is mono block Water Bottling Machine?

It collect rinser, filler and capper in one mono block machine. Made use of rotary bottling technology. The bottling process is in an steel box which make sure the bottling environment clean. It is high automaticly and effective. It is the advanced water bottling machine in the world.

Why monoblock & rotary type bottling machine?

It is the smallest monoblock three in one water bottling machine in the world design by NEPTUNE MACHINERY. It is control by PLC and high automaticly. Tight structure and take small room. Because just aim at 2000 bottles per hour speed so that materials cost less. It is best water bottling machine to first start water bottle business.

Servise

oversea installation

Neptune Machinery Company offers overseas installation and training for their 3in1 water bottling machine. This service ensures that neptune machinery customers from around the world can benefit from professional assistance in setting up and operating the water bottling machine.

Overseas installation and training typically involve sending experienced technicians or engineers to the customer’s location to provide hands-on support. This service is valuable for ensuring the proper installation, calibration, and operation of the water bottling equipment, as well as training the local staff to efficiently manage and maintain the machinery.

Customers considering the purchase of a 3in1 water bottling machine from Neptune Machinery can have confidence in the company’s commitment to customer support and satisfaction through these comprehensive installation and training services.

Warranty

Neptune Machinery offers a one-year warranty for our 3in1 water bottling machine. A warranty provides customers with a certain level of assurance and protection, ensuring that the equipment is free from defects in materials and workmanship for a specified period after the purchase. During the warranty period, customers can typically receive repairs or replacements for parts or components that may malfunction or fail due to manufacturing issues.

This warranty coverage is a positive aspect for customers, as it reflects the manufacturer’s confidence in the quality and reliability of their product. It’s essential for customers to review the specific terms and conditions of the warranty provided by Neptune Machinery to understand the scope of coverage and any conditions that may apply. This information helps customers make informed decisions and provides peace of mind regarding the durability and performance of the 3in1 water bottling machine.

AfterSales

Neptune Machinery offers after-sales support for our 3in1 water bottling machine. After-sales support is a crucial aspect of any industrial machinery purchase. It typically includes services such as maintenance, technical assistance, and spare parts availability, ensuring that customers can maintain and optimize the performance of their equipment over its operational life.

Having reliable after-sales support from neptune machinery helps customers address any issues or challenges they may encounter during the operation of the bottling machine. It also contributes to the overall satisfaction and success of the customers’ business operations. Whether it’s troubleshooting, training, or providing replacement parts, a comprehensive after-sales support system is essential for the smooth and efficient functioning of industrial equipment.

Customers should inquire about the specific details of Neptune Machinery’s after-sales support, including the types of services offered, response times, and any associated costs.

Related products

4000BPH Water Bottling Machine

It included 16psc washing head, 12psc filling head, 6psc capping head. Inlet bottle is air conveyor while outlet is conveyor belt. Whole bottling process is control by PLC. Highly automated and advanced.

| Capacity | 4000 Bottles Per Hour (96000Bottles Per Day-24Hours) |

| Model | 16-12-6 |

4in1 Semiautomatic Water Bottling Machine

4in1 Semi Bottling is a commercial semiaumatic water bottling machine used for washing, filling, capping and labeling any bottle range from 200ml to 2 liters.

| Capacity | 2000 Bottles Per Hour (48000Bottles Per Day-24Hours) |

| Model | 12-12-1-1 |

10000BPH Water Bottling Machine

Fast and stable bottled water machine. It capacity of production can reach 10000 bottles per hour. Easy adjust the capacity of production by the frequency converter

| Capacity | 10000 Bottles Per Hour (240000Bottles Per Day-24Hours) |

| Model | 24-24-8 |